3 Axis Milling and 4 Axis Milling Services

at Greno Industries

Greno Industries provides 3 axis milling and 4 axis milling services to manufacturers in markets such as medical, military, and lifting devices. We mill carbon steel, stainless steel, Inconel, and titanium by removing large amounts of material quickly and efficiently. Greno is service-oriented, keeps plenty of metals in stock, and uses milling equipment made by leading machine manufacturers.

Why Geared Lower is Better for Heavy-Duty Material Removal

Greno’s milling machines are "geared lower" for heavy cutting, drilling large holes, and machining tough materials at slow speeds. When a milling machine is geared lower, it can achieve higher torque. This allows our equipment to pull large-diameter cutters or drills through tough materials without stalling. Lower spindle speeds support more precise RPM ranges.

3 Axis vs. 4 Axis Milling

|

Material |

3‑Axis Milling |

4‑Axis Milling |

|

Carbon Steel |

Excellent machinability with stable chip formation. Ideal for prismatic parts, pockets, slots, and planar surfaces. Lower tooling cost and faster setup for simple geometries. Best for brackets, housings, base plates. |

Enables machining of features on multiple sides without refixturing. Improves accuracy for cylindrical or radial features. Useful for shafts, keyways, flanges, and bolt‑circle patterns. Higher throughput for medium‑complexity parts. |

|

Stainless Steel (300/400 series) |

Good for flat and contoured surfaces with moderate tool wear. Works well for enclosures, plates, and structural components. Heat generation requires conservative feeds/speeds.

|

Reduces setup time for multi‑face machining. Better tool access reduces chatter on tall walls or deep pockets. Ideal for manifolds, valve bodies, and parts with radial symmetry. |

|

Inconel (718/625) |

Machinable but slow due to work‑hardening and heat retention. Best for simple geometries with minimal side‑access requirements. High tool wear and short tool life.

|

Allows continuous tool engagement around curved or cylindrical surfaces, reducing heat concentration. Improves tool life by enabling optimal tool approach angles. Suitable for turbine rings, aerospace brackets, and high‑temp components with multi‑face features.

|

|

Titanium (Grade 2 / Ti‑6Al‑4V) |

Good for planar and prismatic shapes and uses rigid setups to avoid chatter. Effective for plates, blocks, and simple cavities. Heat management and chip evacuation are critical.

|

Enables machining around contours and cylindrical features with fewer setups. Improves accuracy for medical, aerospace, and structural components with complex side features. Better for thin‑wall parts due to improved tool approach and reduced deflection. |

3 Axis Milling Services

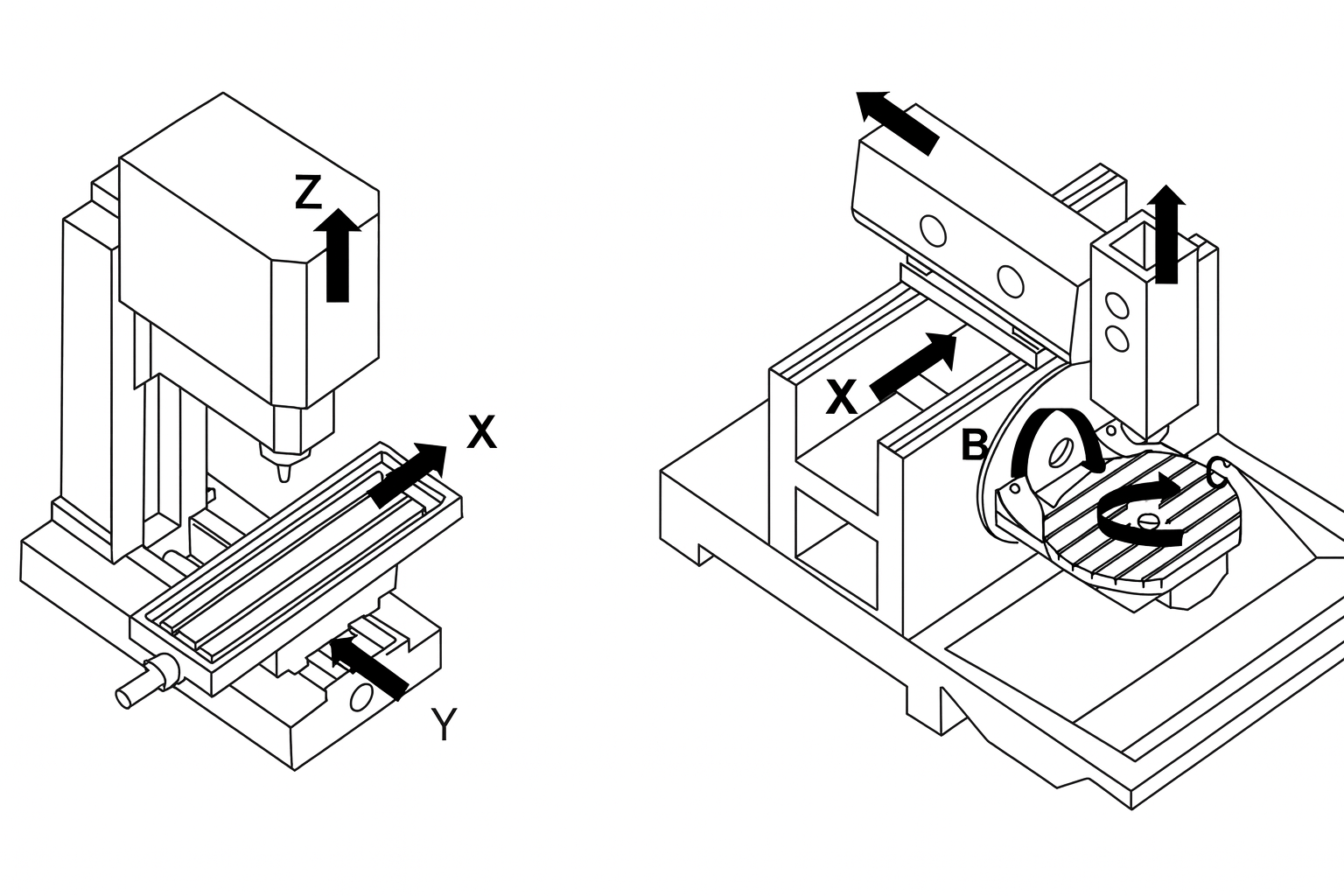

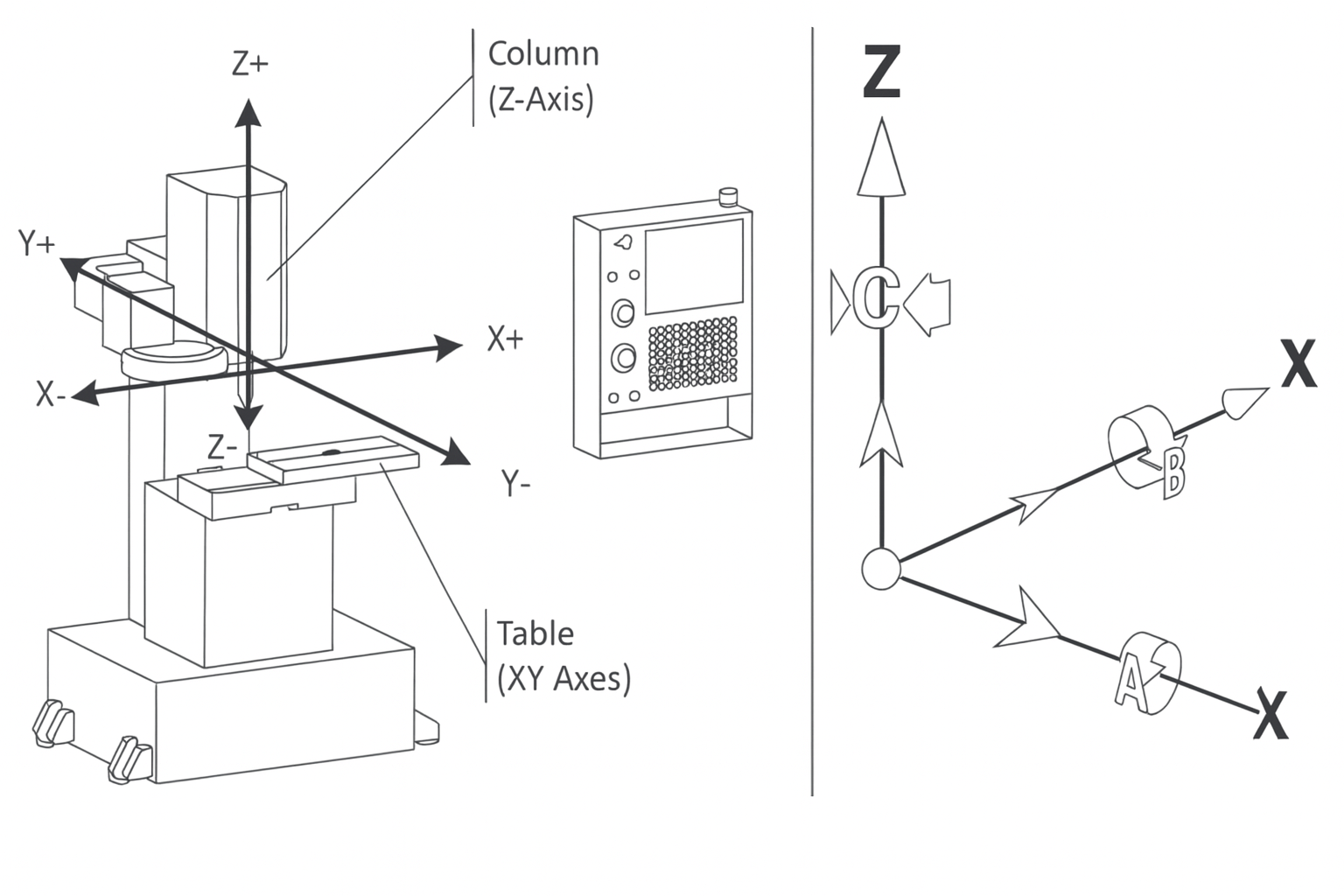

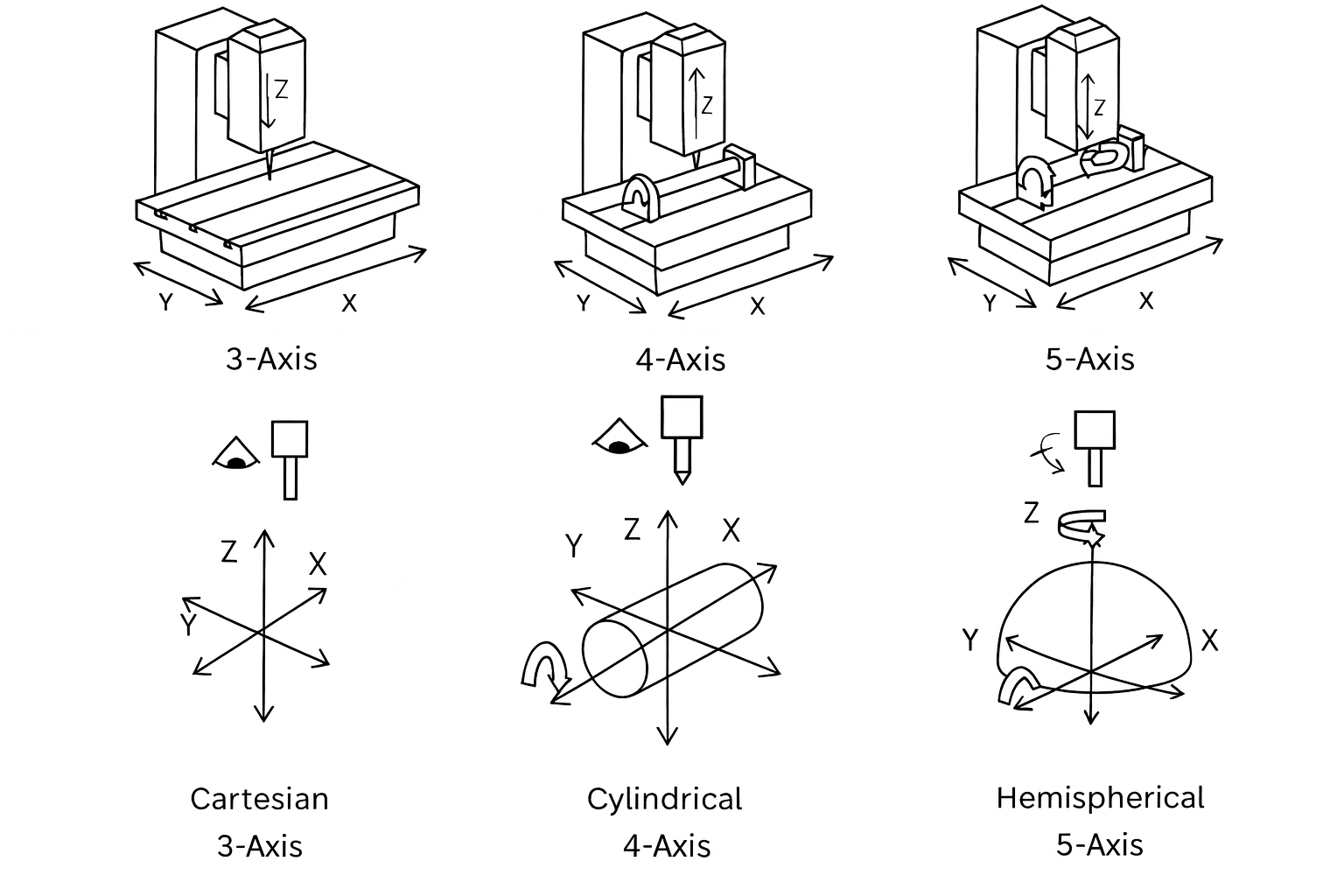

With 3 axis milling, a cutting tool moves along X, Y, and Z axes. This allows the machine to remove material from the top or sides of a stationary workpiece. Because the workpiece remains fixed, 3 axis milling produces consistent, repeatable features with tight tolerances. It’s also cost‑effective because of its simpler setups and shorter programming times.

Applications for 3 axis milling at Greno include:

Flat surfaces and pockets

Simple contours

Drilling, tapping, and slotting

Prismatic shapes

Parts with features that are accessible from a single orientation

4 Axis Milling Services

With 4 axis milling, a rotary axis (the A-axis) rotates the workpiece around the X-axis. This additional degree of freedom allows the machine to reach multiple sides of a part without manual repositioning. The ability to rotate the part reduces setup time and improves feature-to-feature accuracy, especially when features are distributed around a cylinder.

Applications for 4 axis milling at Greno include:

Parts requiring machining on multiple faces

Helical features

Radial patterns

Keyways and splines

Complex cylindrical or angled features

Why 3‑Axis and 4‑Axis Milling Are Sometimes Better Than 5‑Axis

For complex geometries, 5-axis machining offers high precision and accuracy. For a large percentage of engineered components, however, 3-axis and 4-axis machining offers better value, faster turnarounds, and equal or even superior precision. In many cases, 5‑axis machining is unnecessary and adds cost without improving part quality.

Consider 3‑axis or 4‑axis machining when:

The part geometry is prismatic or cylindrical

Features are accessible from one or two orientations

Tolerances are tight but surfaces are simple

Production volume requires cost‑efficient machining

The material is hard and benefits from a rigid setup

Lead time is critical

Engineered components such brackets, housings, plates, manifolds, flanges don’t require the full freedom of 5‑axis machining. Plus, because 3-axis and 4-axis machines have fewer moving components, they provide greater structural rigidity. That’s a major advantage for hard-to-machine alloys like Inconel or titanium. It’s also a plus with milling carbon steel and stainless steel.

Milling Carbon Steel

Carbon steels (1018, 1045, 4140) are widely used for structural components, fixtures, brackets, and machine parts. The high rigidity of 3 axis and 4 axis machinery supports aggressive cutting parameters, and 4-axis rotation is especially useful for machining keyways, bolt circles, and radial features. Milled carbon steels are also used in shafts, flanges, and prismatic parts.

Milling Stainless Steel

Stainless steels (304, 316, 17‑4 PH, 410) require more controlled machining due to work hardening and heat generation. The advantages of 3 axis and 4 axis machining include simplified toolpaths for reduced heat buildup. With 4 axis mills, rotation reduces repositioning and improves dimensional accuracy.

Milling Inconel

Inconel (625, 718) is a nickel‑based superalloy with extreme strength at high temperatures. It’s difficult to machine and requires high cutting forces. The rigidity of 3 axis and 4 axis machines helps maintain tool stability under heavy loads. With 4 axis machining, the advantages include efficient radial roughing and finishing.

Milling Titanium

Titanium (Grade 2, Grade 5 Ti‑6Al‑4V) offers a high strength‑to‑weight ratio but is difficult to machine. The rigid setups of 3 axis and 4 axis machining reduce chatter, a common problem with titanium. The controlled toolpaths help manage heat and prevent tool failure. Applications for 4 axis mills include medical implants, aerospace ranges, and cylindrical components.

Ask Greno for 3 Axis Milling and

4 Axis Milling Services

Greno Industries provides milling services with superior rigidity, faster setups, and excellent performance with carbon steel, stainless steel, Inconel, and titanium.

3‑axis milling excels when the geometry is straightforward, planar, or prismatic. It offers lower cost, faster setup, and excellent repeatability for simpler parts across all four materials.

4‑axis milling becomes the better choice when the part requires machining on multiple sides, radial features, or improved tool access—especially valuable for Inconel and titanium, where heat and tool wear are major concerns.

Contact Greno to learn more and discuss your application.